Diacetyl in Coffee Manufacturing

The Challenge

Diacetyl is a naturally occurring substance with a butter-like

odour which is present in many foods. NIOSH (National

Institute for Occupational Safety & Health) in the USA reported

a link between exposure to vapours containing diacetyl and

decreased lung function and disease. Most studies have

concentrated on exposure to diacetyl in the flavouring industry,

but recent reports have also highlighted the possibility of

exposure to diacetyl, and the related compound 2,3-pentanedione, in

coffee manufacturing, particularly roasting and grinding.

Currently there are no Workplace Exposure Limits (WELs) for either

diacetyl or 2,3-pentanedione but the European Commission Scientific

Committee on Occupational Exposure Limits (SCOEL) has recommended

an 8-hour time-weighted average (TWA) limit for diacetyl of 20 ppb

(parts per billion) and a 15-minute short term exposure limit

(STEL) of 100 ppb (

SCOEL, 2014). However, there is a lack of information on

airborne concentrations of these substances in the coffee

manufacturing sector making it difficult to assess the potential

for personal exposure in their workforce.

The Solution

Most of the methods currently available for measurement of

diacetyl are awkward to use, particularly for personal sampling,

and lack the sensitivity to be able to measure diacetyl and

pentandione down to ppb levels. HSE therefore developed a

sampling and analytical procedure utilising well-proven sorbent

tube and thermal desorption technology. This method is

capable of detecting the presence of both compounds down to sub-ppb

concentrations. In addition to pumped sampling, HSE

determined diffusive uptake rates for diacetyl and pentandione

which allows the sampling devices to be used to take passive

(diffusive) samples. Passive samples are well suited to long

term and personal sampling as they eliminate the need for a

sampling pump. HSE used this new sampling method to carry out

monitoring of both diacetyl and pentanedione at coffee

manufacturing premises, using both personal and static

samples. Sampling was carried out in areas of the plant where

roasting and grinding of the coffee was being carried out, as these

were the areas where concentrations were expected to be the

highest, as well as the packing area and control room.

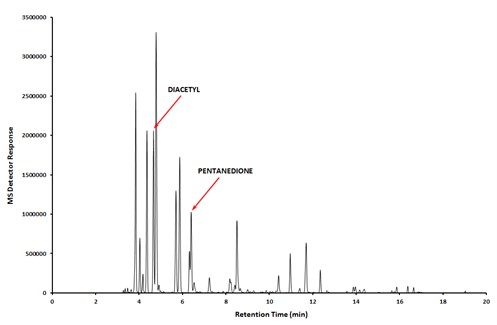

Post-sampling, the samples were analysed for the presence of

diacetyl and pentanedione by thermal desorption, gas chromatography

and mass spectrometry (TD-GC-MS).

The Outcome

The monitoring exercise showed that airborne concentrations of

diacetyl were above the proposed WEL. The highest concentrations

were found in the grinding area, but airborne concentrations in

excess of the 8-hr TWA limit were also detected in the roasting and

packing areas and in the control room. Pentanedione was also

detected, at a level of around a half to a third of those of

diacetyl. These results provide evidence that improvements are

required in order to control potential occupational exposure to

diacetyl and pentanedione in this particular workplace. The results

should also alert other coffee manufacturers to the possibility of

exposure of their employees to diacetyl and pentanedione and the

need for adequate control measures to prevent this and, more

importantly, the ill health that may occur as a result.

The initial work was funded by HSE, but this is now a commercial service

that we offer.

View more examples of our work in this

area.

Back to the top