Catalytic Converters

Suppliers and users of Catalytic Converters must take

necessary precautions to protect workers from Refractory Ceramic

Fibres.

HSE has extensive experience in the identification,

characterisation, measurement and risk assessment of exposure to

fibres. One potential source of hazardous fibres is the fibre mats

contained within catalytic convertors (and diesel particulate

filters). Catalytic converters are manufactured in many different

shapes and sizes, and act to reduce volatile organic compounds

(VOCs), carbon monoxide and nitrogen oxides

(NOx) emitted from vehicle exhaust gases.

In this image of a typical catalytic

convertor, the fibre mat (white, outside) surrounds the metallic

honeycomb structure (yellow, inside), which contains precious

metals and is recyclable. These fibre mats are generally made of

one of three different fibre types: Refractory Ceramic Fibres

(RCF), Poly-Crystalline Wools (PCW) and Alkali Earth Wools

(AEW).

In this image of a typical catalytic

convertor, the fibre mat (white, outside) surrounds the metallic

honeycomb structure (yellow, inside), which contains precious

metals and is recyclable. These fibre mats are generally made of

one of three different fibre types: Refractory Ceramic Fibres

(RCF), Poly-Crystalline Wools (PCW) and Alkali Earth Wools

(AEW).

RCF is classified as a Category 1B carcinogen and end-of-life

catalytic converters should therefore be treated as hazardous

waste. RCFs are also covered by the Registration, Evaluation,

Authorisation, restriction of Chemicals regulations (REACH

2006) and Classification, Labelling and Packaging of substances

(CLP 2009). This means that suppliers and users must be aware that

products contain RCF when selling on or sending for recycling.

Appropriate packaging and labelling must also be used to protect

worker health by preventing accidental exposure to RCF during

disposal and recycling.

However, neither PCW nor AEW are classified as carcinogens and,

therefore, are not subject to the same regulations. PCW and AEW are

visually very similar in appearance to RCF and it is therefore

impossible to differentiate between them by visual inspection.

Catalytic converter manufacturers and suppliers will typically

replace their customers' existing stock with their own products.

Without testing, large numbers of converters containing RCF could

be sent for recycling (extraction of precious metals) or sold on to

third parties without the appropriate precautions being taken.

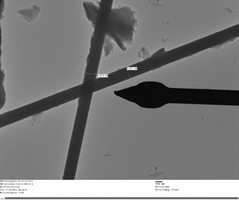

The Transmission Electron Microscopy (TEM)

techniques used by HSE can, however, differentiate between the

fibre types, identifying which products contain RCF and which

contain unregulated PCW or AEW. This protects workers by reducing

the likelihood of accidental exposure to RCF during disposal and

recycling. It also allows significant cost savings by identifying

which converters require segregation and special treatment and

which do not.

HSE is UKAS accredited

(ISO 17025) for the identification of inorganic fibres by TEM/EDX.

For further information, please contact

Sample Registration (0203 028 3383).

More information on the science

The morphology (appearance) of the three fibre types is similar,

making them difficult to differentiate. However, the techniques

used at HSE's Science and Research Centre allow this to be

done.

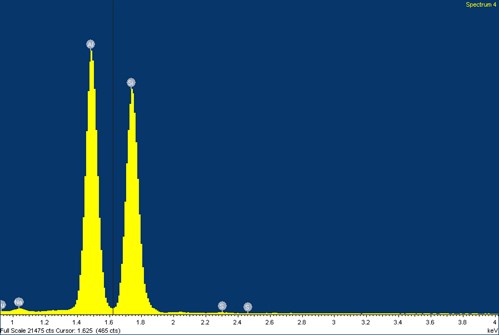

Energy Dispersive X-Ray Spectroscopy (EDX) is a

technique that reveals the chemical composition of fibres. The

chemical composition of AEW is sufficiently different from RCF and

PCW to allow differentiation by EDX. RCF and PCW, however, are very

similar and therefore require a further technique called

Selected Area Electron Diffraction (SAED).

TEM image of RCF fibres

EDX spectrum from RCF

fibre

The structure within PCW is largely crystalline and will

therefore produce a pattern (see below) when SAED is applied,

whereas the amorphous structure within RCF does not produce a

pattern.

SAED pattern from PCW showing

concentric ring pattern

In summary, a combination of the EDX and SAED techniques applied

using HSE's TEM instrument allows the three different fibre types

to be successfully differentiated.

Back to the top