Carcinogens in the electroplating industry

The Challenge

In the electroplating industry, hexavalent chromium and nickel

compounds are widely used in deposition plating processes. Both are

classified as skin and respiratory sensitising agents as well as

being carcinogens; it is therefore important, and a legal

requirement, that exposure be reduced to levels as low as

reasonably practicable (ALARP).

An estimated 3,000 workers are potentially exposed to nickel

and/or hexavalent chromium in the electroplating industry, through

inhalation of dusts, fumes and mists, by absorption through the

skin, or by ingestion as a result of hand-to-mouth contamination.

Consequently, efforts to reduce worker exposure rely on good

working practices, appropriate engineering controls and suitable

personal protective equipment used correctly.

The Solution

This HSE study, with the cooperation of the Surface Engineering

Association, looked at whether repeat biological

monitoring could drive sustainable improvements in exposure control

by raising individual worker risk awareness and improving worker

understanding of exposure pathways.

Workers at 49 electroplating companies took part by providing

post-shift urine samples for three consecutive days. These sets of

samples were collected at the start of the project then at 6 and 12

month intervals, to assess levels of exposure to chromium and

nickel. Following the results of the initial sampling, direct

feedback and targeted advice was provided.

Routes of exposure were also investigated by conducting hand

wash sampling, taking surface wipes and air sampling.

The Outcome

Many companies were found to be controlling exposures within the

current guidelines, although there were still areas for

improvement. In 15 of the 49 companies, more than half the workers

had elevated urinary nickel levels; the same was true for urinary

chromium levels at 13 companies. After HSE gave feedback and

guidance, worker exposures were significantly reduced in these

companies in the follow-up sampling rounds. Repeat biological

monitoring saw reductions in the range of 30 to 40% for nickel and

20 to 30% for chromium.

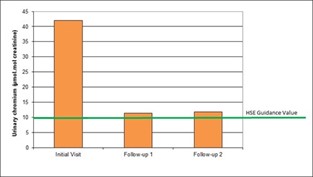

The graph below shows the reduction in urinary chromium levels

for a maintenance worker as a result of advice given after the

initial sampling, with follow-up values about one-quarter of the

initial values.

The study demonstrated that biological monitoring is a very

effective tool for exposure assessment and that repeat testing can

drive improvements in exposure control and personal risk awareness,

leading to reduced levels of nickel and chromium exposure.

View more examples of our work in this

area.

For more information about how we could do something

similar for you, email us at: registration.sample@hse.gov.uk

Back to the top